Pre-Production & Engineering

Investment in engineering and constructability review during the quoting process helps projects avoid higher costs and delays during fabrication.

We take a holistic view of your parts to make sure that we first understand all the required details and specifications before generating any pricing.

Our goal is to meet your design intent at the lowest cost. We can provide these cost-effective metal fabrication solutions because of our knowledge of various manufacturing processes, tooling limitations, and material properties. The result is an optimized part that strikes a balance between function and cost.

When you work with Fast Trak Metal Fabrication, you can request at no additional cost:

Fabrication

Through the pre-production and engineering process, we know how to best execute fabrication of your parts before we even receive a purchase order. Once we receive that order, we can immediately move into programming and production.

Our established internal processes and enterprise resource planning (ERP) software allows your project to seamlessly transition from one department to the next.

This benefits you by not only shortening lead times, but also by reducing the chance of receiving parts that are out of tolerance or incomplete. Our rigorous quality management procedures and the efforts of everyone at Fast Trak make this possible. By also offering alternatives for optimal quantity yields, our experience and efficiency will help you to procure the best part possible at a competitive price.

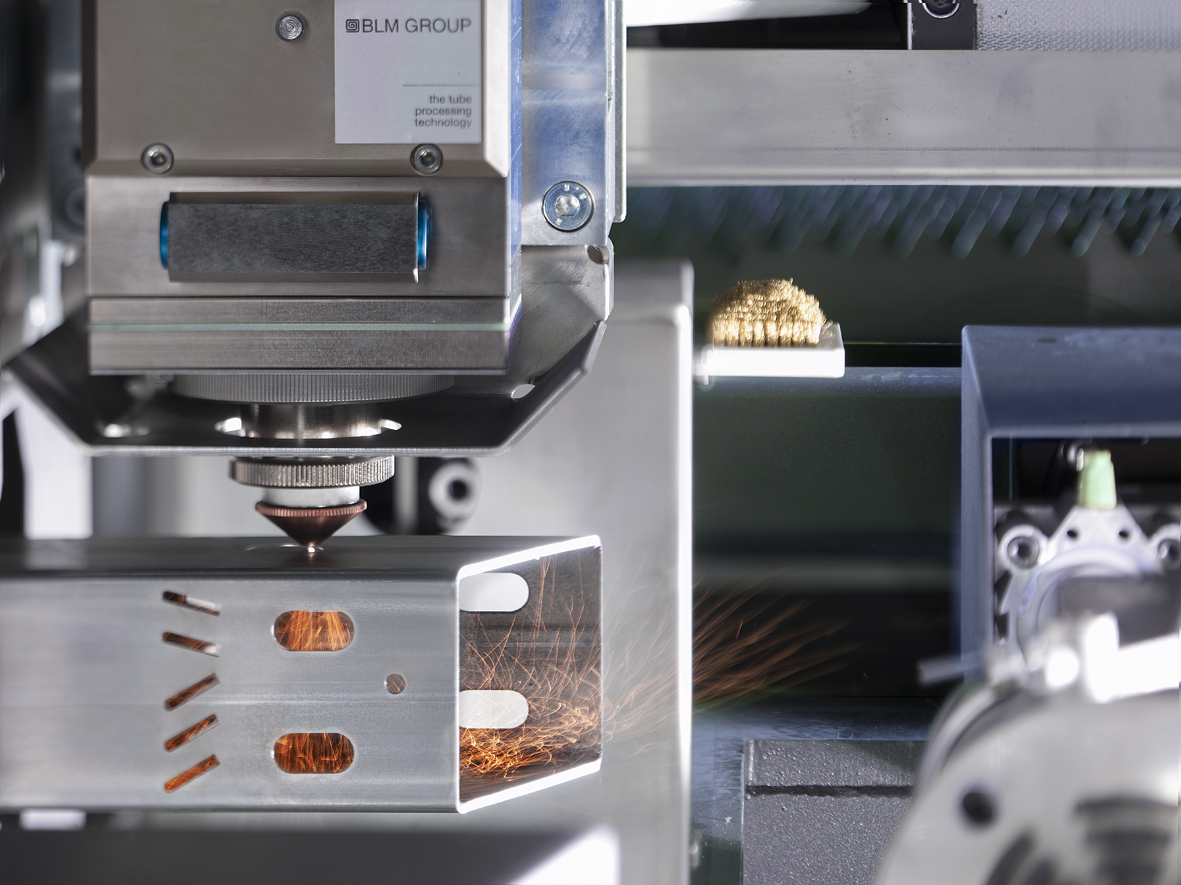

Laser Cutting – TUBE, PLATE & SHEET

Laser cutting is our specialty.

At Fast Trak Metal Fabrication we stock a variety of ferrous and non-ferrous metals to help us to maintain short turnaround times. The most common materials that we work with are carbon steel, stainless steel, aluminum and galvanized steel.

Our 10kw Combination Tube/Sheet Laser allows us to work with the following range of material thicknesses:

| Material | Min to Max |

|---|---|

| Round Tube | .500” to 5.00” |

| Square Tube | .500” to 4.00” |

| Mild Steel | 24 gauge to 1.125” thick |

| Stainless Steel | 24 gauge to 1.50” thick |

| Aluminum | .020” to 1.375” thick |

| Brass | .025” to .500” thick |

| Copper | .025” to .375” thick |

CNC PRESS BRAKE FORMING

Forming is our most requested value-added service.

When paired with our precision-ground tooling, our CNC Press Brakes can satisfy all your forming needs. We have a forming capacity available up to 200 tons and 12 feet of bend length.

Our team routinely checks formed parts for accuracy to ensure that each part will arrive in tolerance as expected.

CNC MACHINING

Our 3-axis vertical CNC mill can accommodate simple drilling and tapping to pocket milling of complex geometries all while holding tolerances as tight as +/- 0.002”.

We work with a local network of partners to provide completed machined parts that require more than our in-house services.

MANUFACTURED ASSEMBLY

This is where we shine. Send us ONE P.O. to streamline your purchasing efforts. Parts are delivered complete, not piecemeal.

We offer value-added services that enable you to avoid multiple vendors, saving you time and money. Our production flexibility allows us to strategically schedule work orders to minimize lead times. By combining key industry partnerships with our state-of-the-art equipment, we are able to provide you with the finished assembly that you need.

Don’t see what you need on this list? Just ask. We will source whatever service you need or guide you to a trusted manufacturing partner.

Supply CHain Services

Augmented supply chain services are a natural extension of our fabrication expertise that can provide many benefits to our customers.

We offer a flexible and linear turnkey experience with our Supply Chain options.

You will experience reduced overhead and operational costs associated with storage, labor, and shipping with our FLEX program. When you work with us to help manage your supply chain, your team can dedicate more time to elements of your core business like product development and customer service. Our supply chain services will help you meet your Inventory Management, Packaging, and Fulfillment at a lower cost.